- Empty cart

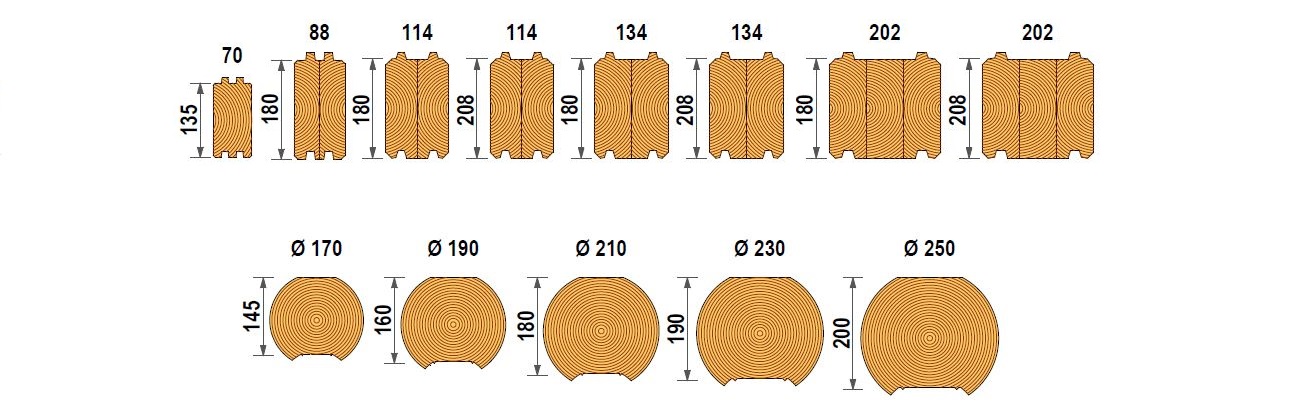

The selection of wall material shall be based on the particular features of the house project and future use of the building. Most log house projects displayed on the homepage enable construction with round as well as square logs. Smaller garden houses and saunas can be built with mill beams with wall profile up to 88 mm. Thicker log walls have naturally also better thermal characteristics.

Ritsu offers following log profiles:

Summer cottages and saunas are usually constructed with square mill beams with the thickness 88 or 114 mm or round logs with the diameter 170mm. Garden houses are usually constructed with dried fir wall profiles with the thickness 70 mm (sometimes also 88 mm).

Log parts of log homes made of square logs and log houses with city corner are usually made of laminated pinewood with the thickness 114 or 202 mm. In case of a house solution with combined wall the massive (202 mm) log walls can be connected with 114mm thick walls. Round log homes are usually made of natural pinewood with the diameter 190, 210 or 230 mm.

Round logs are always made of pinewood, while square mill beams are made of fir or pinewood. External walls of the houses made of square material can be insulated, if necessary, while a round log wall will remain single. All materials used for the production of the buildings are chamber dried.

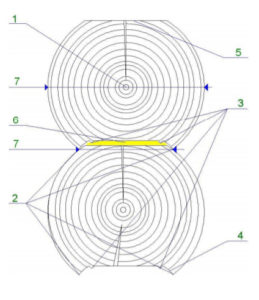

SQUARE LOG PROFILE

For square log production we use only the best quality wood, especially chosen and imported from Northern Finland to be able to offer finest quality with highest standards.

- Lamellas have been cut along the timber core and glued together leaving the core lines to the outside. Thus the possibility of the formation of cracks has been taken to a minimum.

- Horizontally milled tips will ensure the strength and stability of the wall and prevent air movement. Insulation strips are installed on top of the tips to ensure thermal stability.

- The zones of the three slant system invisible from the outside will give the wall rigidity, prevent the intrusion of airflow and humidity between the logs.

- The zones of the three slant system visible from the outside will give the wall a jointed appearance and aid quick removal of rainwater from the external wall.

- The width of the squared log will affect the durability and thermal stability of the building. The thicker the logs of the external wall, the more thermally stable the house.

- Middle wide horizontal milling and an air chamber between upper and lower logs will ensure the stability of the building also after the settlement of the walls characteristic of a log house.

- We use hidden pegs inside walls and thread laths in the corners of the house when assembling. They will ensure the stability of the building.

- Protruding log ends are cut to a 45-degree angle. Hip logs are sawed according to the prescribed roof inclination.

- Inserted ceiling beams are from a non-profiled smooth squared log in the case of bigger houses.

- Manufactured logs are ready to be installed. All borings inside the log for the purposes of power wires, thread laths, hidden pegs and electrical sockets are made in the factory.

- The logs are impregnated when ready

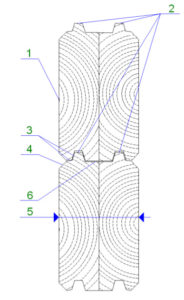

ROUND LOG PROFILE

The round log profile developed by Ritsu is unique and recognized among customers all over the world.

- A dried log is calibrated into required dimension, taking into account the center of the core. This method ensures straightness of the log and prevents further twisting and deformation.

- The edges of the log groove enable extra tight compression of logs in the wall. These prevent the intrusion of airflow and humidity between logs from the outside and heat loss from inside a house/building.

- The internal locks of the groove sink down to the base surface of log beneath due to the weight of the house, forming 3 airtight chambers. These chambers are one of the most important factors ensuring heat stability in the case of the groove type.

- Inner edges of the groove fit the diameter of a round log.

- Log moves on the technological base surface on production lines. Thus the edges of the groove will be protected.

- Inside the groove, between internal locks the insulation material will be installed, which will prevent air movement inside the groove.

- In addition to the groove profile, the diameter of the log and width of the groove are both important to the thermal stability of the wall.

- Hidden pegs are used at mounting walls, which will keep the wall together as one. Thread laths are used in the corners of walls.

- There is always a wadding groove in corner tenons, the filling of which with insulation material will ensure even better thermal insulation. The decorous ends of protruding logs are without a wadding groove.

- Ends of vertical pillars are profiled to fit with horizontal wall logs.

- Round logs do not have longitudinal groove when used as ceiling beams. So it is not necessary to use any wooden strips to cover the grooves.

- For better instalments of flat objects like electricity switches, sockets, radiators and window battens we can mill solid bases on round log side(s).

- We take care of produced logs even during packing process by protecting sharp locks to preserve exact shape till erection process of the house takes place.

- Manufactured logs are ready to be assembled/installed: all drillings inside the logs for electricity wires, thread laths, dowels are made; logs are impregnated before the packing after all millings and cuts are done; apertures for windows and doors are fully or partly cut into height measure; cable end logs are cut into necessary measure.

Many of the production solutions give extra decorative value to the building, while the technology makes construction works easier and quicker.